Manufacturing

No less than ten stages are involved in the manufacture of EGIDE helmets, whether made from leather or high-tech materials, and whether for cycling, skiing, or horse-riding. Each of these stages is carried out by hand, in Nantes and Cholet.

1

Selection and treatment of the leather

The full-grain leathers for EGIDE helmets are chosen from the most renowned tanneries. They are then treated as a mass, ensuring they withstand the extremes of rain, UV rays, and surface aggressions.

2

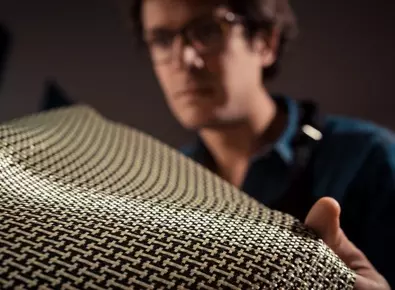

Carbon / Kevlar / Linen: SELECTION AND TREATMENT

EGIDE has selected carbon, Kevlar, and linen as its high-tech materials of choice. Used in the aeronautical industry, for bullet-proof vests and other protective coatings, these materials ensure that the helmets are robust, light, and safe. The surface is then covered with an anti-scratch varnish.

3

Leather-CUTTING

At the next stage of manufacture: the leathers are cut by hand, to ensure that only those parts that contain no imperfections are identified and selected for use by the skilled leather craftsman.

4

Carbone / Kevlar / Linen: The CUTTING

As for leather, the high-tech materials are cut by hand, but this time using a die-cutting punch and strict draping plans. The craftsman’s experienced eye ensures that there are no defects in the pieces which are chosen.

5

Leather-STITCHING

The seams and the stitching are done by hand, using a special thread, which is chosen for its high resistance to rain, UV rays, and surface abrasions.